Help:TRS19 Driver Controls Steam

(→Controls UI) |

(→Controls UI) |

||

| Line 54: | Line 54: | ||

The Train Brake control can work in two ways in Trainz. | The Train Brake control can work in two ways in Trainz. | ||

| − | : | + | :Non Self Lapping |

:The first is a non self lapping brake. Most older steam locomotives will use this form of train brake. This Train Brake type provides 5 positions: | :The first is a non self lapping brake. Most older steam locomotives will use this form of train brake. This Train Brake type provides 5 positions: | ||

: =====Release===== | : =====Release===== | ||

Revision as of 19:51, 16 July 2018

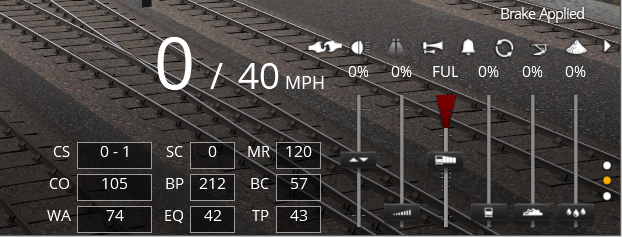

The Driver Realistic Steam Controls UI provides the controls and information needed for you to drive your steam locomotive in Realistic Controls mode (formerly CAB Mode). Selecting the Realistic Controls option in the Driver UI will automatically set the session to run with Realistic Controls.

The Realistic Steam Controls UI is divided into two sections, the Status Display and the Controls.

Contents |

Status Display

The Status Display shows the essential information for driving a steam locomotive in Trainz.

Coupler Slack (CS)

This display tells you the current drawbar force x1000 (so 1-2 indicates a drawbar force between 1000LBF and 2000LBF).

Coal Level (CO)

The Coal Level display tells you the current level of coal in the firebox. 100% is the optimum level of coal in the firebox, creating the most heat and hence the most steam. When working hard you should aim to keep the coal level near 100%. When approaching a steep up hill gradient, you should add more coal above 100% to allow the fire to burn down to 100% as you approach the gradient to make as much steam as possible. When working lightly, such as down hill, you can let the coal level drop somewhat below 100% as you will not need to generate as much steam. Remember that there can be a delay between adding coal, and making steam, as adding coal may lower the fire temperature and will take time to ignite and burn.

Water Level (WA)

The Water Level display tells you the current water level, as on the gauge glass in the cab, in the boiler of the locomotive. If you run out of water in the boiler, the fusible plug will melt (boiler pressure will disappear to 0PSI) and you will no longer be able to drive the locomotive. Good practice is to keep the boiler water level between 50-70%. The amount of water in the boiler will affect the volume of steam available, more water will restrict how hard you can drive the locomotive before the boiler pressure drops.

Steam Chest Pressure (SC)

The Steam Chest Pressure display tells you the current pressure in the Steam Chest, which gives you an approximate idea of the pressure of steam in the cylinders. This indication can be helpful for operating the Cut-Off on the locomotive. For maximum efficiency, and tractive effort, the Steam Chest Pressure will generally be close to the boiler pressure of the locomotive. As you gain speed, you will need to reduce the Cut-Off to keep the Steam Chest Pressure up. This value is only important if you are working the train hard, such as trying to reach the track speed limit or working up a steep grade. When coasting, or working lightly, the steam chest pressure should be low as you will not need to use as much steam.

Boiler Pressure (BP)

The Boiler Pressure display tells you the current steam pressure in the boiler. When working hard you should aim to keep the boiler pressure close to, or at, the maximum working pressure (this is the pressure at which the safety valves will start to blow off, releasing excess steam). With practice you should be able to keep the boiler pressure just below the pressure that the safety valves operate. Good practice is to never have the safety valves release steam, as this is a waste of coal and water; however this may be unavoidable if you need to unexpectedly use less steam (ie stop for an unexpected signal).

Equalizing Reservoir Pressure (EQ)

The Equalizing Reservoir Pressure display tells you the current pressure in the Equalizing Reservoir on your locomotive.

When you apply a non self lapping train brake, the Equalizing Reservoir Pressure will drop until the handle is moved to the lap or release positions. When you apply a self lapping train brake, the Equalizing Reservoir Pressure will drop until it reaches the corresponding pressure of the brake handle's position (This may vary between locomotives).

When you are driving a heavy train, you should use the Equalizing Reservoir to judge the reduction of air in the train brake instead of using the Brake Pipe Pressure. This is because long trains may take some time for changes in the brake pipe pressure to propagate along the length of your train.

Main Reservoir Pressure (MR)

The Main Reservoir Pressure display tells you the current pressure of the Main Reservoir on your locomotive. The Main Reservoir is used to release and recharge the brakes when released after a brake application (or after coupling to a wagon/consist). If your Main Reservoir pressure gets too low, you will not be able to recharge the air in the train brake, and hence may not be able to apply the train brake again.

Brake Cylinder Pressure (BC)

The Brake Cylinder Pressure display tells you the current pressure in the brake cylinders on your locomotive. Any value above 0 indicates that the brakes on your locomotive are applied to some degree, and may slow or stop your train. The locomotive brakes may be applied with both the train brake and independent brake. When the train brake is applied, you can 'bail off' the locomotive's brake cylinder (this will release the locomotive's brakes) by pressing the 'D' key.

Train Pipe Pressure (TP)

The Train Pipe Pressure display tells you the current pressure in the train brake pipe. The 'release' pressure may vary, but generally will be around 70PSI/480KPA. When you apply the train brakes, the train pipe pressure will drop until it matches the Equalizing Reservoir Pressure; keep in mind that on long trains there may be several seconds before the train pipe pressure makes a noticeable change or reaches the Equalizing Reservoir Pressure. You should always use the Equalizing Reservoir Pressure to judge how much you have applied the brakes, not the Train Pipe Pressure.

Controls UI

The Controls UI provides access to the core controls of a steam locomotive. Some steam locomotives may have additional controls that are accessed within the cab view, or via the keyboard. These additional controls are not covered here, as they may vary depending on the locomotive.

Reverser

Also known as the cut-off, the reverser control provides you direction control and cut-off control on a steam locomotive. The cut-off controls how long steam is admitted from the steam chest into the cylinders for each stroke of the cylinders; at higher speeds you should reduce cut-off to reduce the amount of steam being used by the cylinders, and hence allow steam to be used more efficiently and to allow greater speed.

Regulator

The regulator control of a steam locomotive controls how much steam is supplied from the boiler to the steam chest. The more you open the regulator, the more steam you will supply to the steam chest and hence to the cylinders. When starting off, you should gently open the regulator otherwise you may slip the wheels. If you are struggling up a hill, try quickly 'pumping' (closing and re-opening) the regulator to provide short bursts of steam to the cylinders. On many locomotives, once moving, they will operate best with the regulator close to fully open and then use the cut-off to help control speed; you should still close the regulator off either partially or fully if you do not need to power the locomotive (ie when running down hill, or on level track with a light train).

It may take some practice to get used to controlling your speed and power using both the regulator and reverser.

- ===Train Brake===

The Train Brake control can work in two ways in Trainz.

- Non Self Lapping

- The first is a non self lapping brake. Most older steam locomotives will use this form of train brake. This Train Brake type provides 5 positions:

- =====Release=====

- The Release position will release the trains brakes. Trainz does not support partially releasing the air brake, any increase in pressure will release the brakes.

- =====Lap=====

- The Lap position will 'hold' the train brake pipe pressure after making a brake application. Although it might stop the train pipe pressure increasing after release, this will not hold the brakes partially released.

- =====Apply=====

- The Apply/Application position will start to release air from the Equalizing Reservoir, which in turn will cause air to be released from the Train Brake Pipe. As the Train Brake Pipe pressure drops, the brakes will be applied harder. As the Train Brake Pipe pressure can take a while to drop, :you should use the Equalizing Reservoir Pressure to gauge how much you have applied the brakes.

- =====Emergency=====

- The Emergency position will very rapidly release air from the Equalizing Reservoir and hence the Train Brake Pipe, making an emergency brake application. This should only be used in an emergency, as applying brakes this hard can damage merchandise or even the train!

- =====Handle Off=====

- The Handle Off position, on some prototype locomotives, allows the handle to be removed from the brake valve. In Trainz, this position does not provide any actual brake function.